The ideal solution for transmitting motion and mechanical power. LUAN DUNG transmission chains are extremely versatile, strong and designed to withstand unforeseen loads or possible stop and go.

The mechanical qualities of LDC transmission chains ensure a long life of service and performance in any field of application.

The anti-rotation flats, the strong riveting system, the treatments with specific depths and the careful selection of raw materials and the checks performed throughout the entire manufacturing process produce a high accuracy chain, with low friction, wear resistant and a service life above average.

The models available in the catalogue are simple, duplex and triplex roller chains manufactured according to standard ISO DIN 8187; ASA DIN 8188, DIN 8164, rotary chains with offset links.

Available in different materials, depending on the intended use, the power to be transmitted and the work conditions.

Specific heat and surface treatments improve the resistance to wear, oxidation and corrosion.

The chains available are made of different materials: case hardening steel, hardened and tempered steel, and stainless steel.

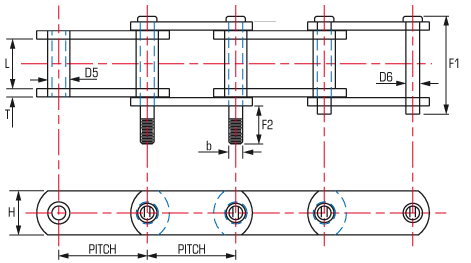

Wash Box Chains Specifications

Wash Box Chain is primarily used in the mining industry, coal preparation plants, and corrosive environments. The wash box chain that we offer is engineered and manufactured to withstand the abrasion and tough environments that it may be exposed to under ground. Besides the chain we also offer a full line of wash box chain sprockets, as well as motors, reducers, bearings, and more. LDC Roller Chain and Sprockets aims to be a one stop shop for all your mining application needs. For more information or to get a quote please contact us and we will be happy to assist you.

|

Chain Number |

Pitch |

Space |

Chain Width |

Inside |

Pins |

Bushings |

Sidedbars |

Attachments |

Approx. |

|||||

|

Overall |

Diameter |

Material |

Diameter |

Material |

Thickness |

Height |

Material |

|||||||

|

F1 |

L |

D6 |

D5 |

T |

H |

F2 |

||||||||

|

inches |

inches |

lbs/ft |

||||||||||||

|

LDC3075H/D3X4 |

3.075 |

Ev. 4th |

4.00 |

1.31 |

0.75 |

ACHCP |

1.25 |

CCH |

0.38 |

1.75 |

CHT |

0.75 |

1.25 |

10.2 |

|

LDC3075H/D3X6 |

3.075 |

Ev. 6th |

4.00 |

1.31 |

0.75 |

ACHCP |

1.25 |

CCH |

0.38 |

1.75 |

CHT |

0.75 |

1.25 |

9.8 |

- Specifications

Drawing Number

19501 Pitch

3.075 in E - Inside Width

1.310 in B - Head to CL Chain Width

1.630 in C - End to CL Chain Width

1.810 in B+C - Overall Chain Width

3.440 in Approx. Weight

4.600 lb/ft - Pin Specifications

G - Pin Diameter

0.680 in Pin Material

Alloy Heat-treated - Bushing Specifications

D - Bushing Diameter

1.250 in Bushing Material

Carbon Case Hardened - Sidebar Specifications

H - Sidebar Height

1.500 in T - Sidebar Thickness

0.380 in Sidebar Material

Carbon Heat-treated - Attachment Specifications

I

2.060 in J

4.940 in K

0.670 in L

0.630 in M

0.500 in N

0.250 in

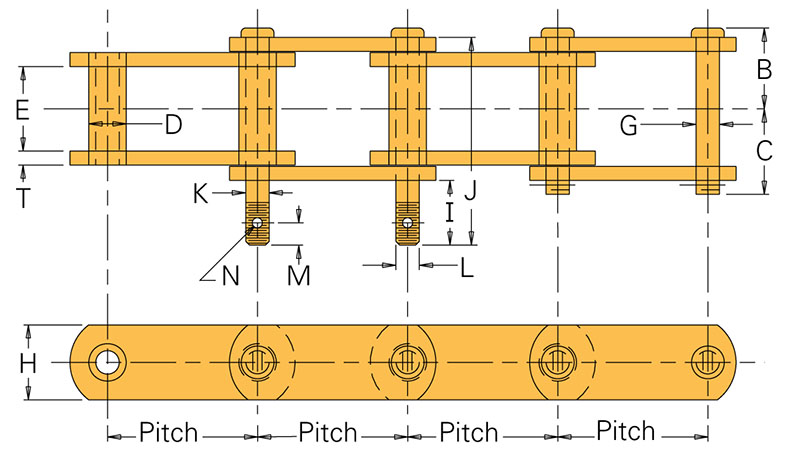

Shuttle Car Chains

Shuttle cars are designed to efficiently remove cut material from the mine work face in such a manner as to enhance the performance of continuous mining equipment in order to maximise productivity. Two standards styles are illustrated but this is not exhaustive, many bespoke types are available as special production.

Engineering Class Shuttle Car Chain – Style LDC

|

Chain Number |

Pitch |

Spacing |

Chain Width |

Inside |

Pins |

Rollers |

Sidedbars |

Attachments |

Approx. |

|||||

|

Overall |

Diameter |

HTC |

Diameter |

HTC |

Thickness |

Height |

HTC |

|||||||

|

F1 |

L |

D6 |

D2 |

T |

H |

R |

S |

|||||||

|

inches |

inches |

lbs/ft |

||||||||||||

|

LDC2609/BM5X6 |

2.609 |

Ev. 6th |

2.91 |

1.13 |

0.56 |

C |

1.13 |

C |

0.31 |

1.63 |

T |

1.28 |

0.66 |

6.3 |

|

LDC2609/BM5X8 |

2.609 |

Ev. 8th |

2.91 |

1.13 |

0.56 |

C |

1.13 |

C |

0.31 |

1.63 |

T |

1.28 |

0.66 |

6.3 |

|

LDC3075/BM5X6 |

3.075 |

Ev. 6th |

3.56 |

1.50 |

0.63 |

C |

1.25 |

C |

0.38 |

1.75 |

T |

1.28 |

0.66 |

8.8 |

Heat Treatment code (HTC)

T – Hardened and Tempered

C – Case Hardened

I – Induction Hardened

Bush Class Chains with Attachment

Hardened Steel Bush (HSB) Chains are designed as a substitute for combination chains where conditions require a heavier, more rugged chain. They are extremely durable without excessive weight. HSB chains are well suited to medium to heavy conditions. SS102B, SS131, SS188 all stocked in hanoi warehouse. Available in LDC® brand.

| Attachment No. |

Chain No. | Chain Type |

Dimensions | Mass ㎏/m |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | R | C | F | E | O | I | ||||

| F2 | SS488 | 3 | 35.0 | 50.0 | 15.0 | 24.0 | 51.6 | 75.0 | - | 9.5 | 6.0 | 8.4 |

| SS4103 | 4 | 80.0 | 101.5 | 21.5 | 28.0 | 114.3 | 151.5 | - | 13.5 | 7.9 | 23.6 | |

| SSH124 | 4 | 70.0 | 95.0 | 25.0 | 30.1 | 136.0 | 166.0 | - | 12.0 | 7.9 | 21.5 | |

| K1 | SS488 | 5 | 21.4 | - | - | - | 96.8 | 128.6 | 28.6 | 7.0 | 6.3 | 7.7 |

| SS0340 | 6 | 38.0 | - | - | 50.8 | 111.2 | 143.0 | 31.8 | 11.12 | 7.9 | 10.9 | |

| A22 | SS488 | 7 | - | - | - | 33.13 | 48.4 | 64.3 | 28.4 | 7.2 | 9.5 | 6.3 |

| A42 | SS0340 | 7 | - | - | - | 80.8 | 63.5 | 79.4 | 38.1 | 12.7 | 9.4 | 12.8 |

(in.)

| Attachment No. |

Chain No. | Chain Type |

Dimensions | Mass ㎏/m |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | R | C | F | E | O | I | ||||

| F2 | SS488 | 3 | 1-3/8 | 1-31/32 | 19/32 | 15/16 | 2-1/32 | 2-61/64 | - | 3/8 | 16/64 | 5.6 |

| SS4103 | 4 | 3-5/32 | 4 | 27/32 | 1-7/64 | 4-1/2 | 5-31/32 | - | 17/32 | 5/16 | 15.9 | |

| SSH124 | 4 | 2-3/4 | 3-47/64 | 63/64 | 1-3/16 | 5-23/64 | 6-17/32 | - | 15/32 | 5/16 | 14.4 | |

| K1 | SS488 | 5 | 27/32 | - | - | - | 3-13/16 | 5-1/16 | 1-1/8 | 9/32 | 1/4 | 5.2 |

| SS0340 | 6 | 1-1/2 | - | - | 2 | 4-3/8 | 5-5/8 | 1-1/4 | 7/16 | 5/16 | 7.3 | |

| A22 | SS488 | 7 | - | - | - | 1-5/16 | 1-29/32 | 2-17/32 | 1-1/8 | 9/32 | 3/8 | 4.2 |

| A42 | SS0340 | 7 | - | - | - | 2 | 2-1/2 | 3-1/8 | 1-1/2 | 1/2 | 3/8 | 8.6 |

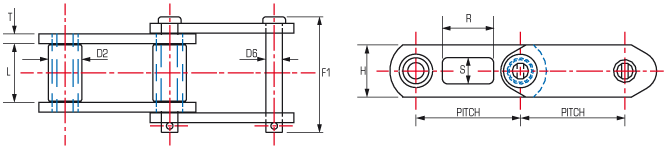

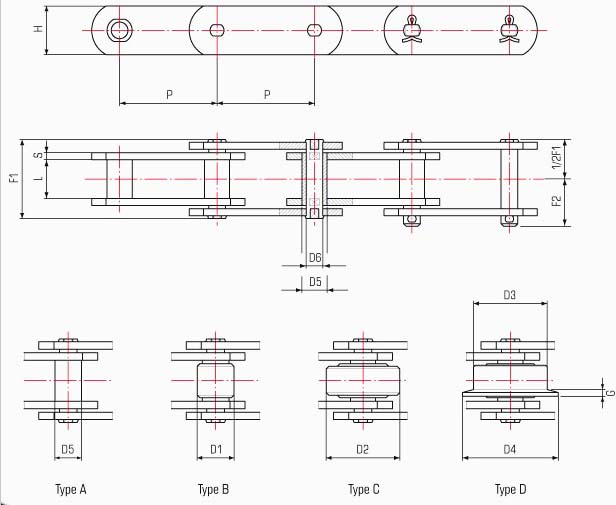

LD Series Chains

This LDC Din series chain is a specific German standard as BS is British. This series is comparable to M and in some sizes identical. The range is not as extensive in terms of higher strengths, but again is available in bush, standard and large roller together with flanged roller. This series is encountered across the whole spectrum of industry but notably in timber products and construction machinery. The Din standard establishes very specific parameters for materials, and construction.

|

Metric Chains (LD Series) DIN 8165 |

||||||||||||||||

|

Chain |

P |

Working |

Average |

Over-All Pin & Cotter |

Rollers |

Bushings |

Between |

Sidebars |

Pins |

|||||||

|

Style |

Flange |

Diameter |

Thickness |

Height |

Diameter |

|||||||||||

|

Bush Type |

F1 |

F2 |

D1 |

D2 |

D3 |

D4 |

G |

D5 |

L |

S |

H |

D6 |

||||

|

mm |

kN |

kN* |

kg/m |

mm |

||||||||||||

|

LD63 |

63 |

64 |

75 |

3.46 |

45 |

26 |

26 |

40 |

50 |

63 |

5 |

18 |

22 |

4 |

30 |

12 |

|

LD63 |

80 |

64 |

75 |

3.73 |

45 |

26 |

26 |

40 |

50 |

63 |

5 |

18 |

22 |

4 |

30 |

12 |

|

LD63 |

100 |

64 |

75 |

2.92 |

45 |

26 |

26 |

40 |

50 |

63 |

5 |

18 |

22 |

4 |

30 |

12 |

|

LD63 |

125 |

64 |

75 |

2.67 |

45 |

26 |

26 |

40 |

50 |

63 |

5 |

18 |

22 |

4 |

30 |

12 |

|

LD63 |

260 |

64 |

75 |

2.45 |

45 |

26 |

26 |

40 |

50 |

63 |

5 |

18 |

22 |

4 |

30 |

12 |

|

LD90 |

63 |

100 |

115 |

5.72 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD90 |

80 |

100 |

115 |

5.20 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD90 |

100 |

100 |

115 |

4.67 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD90 |

125 |

100 |

115 |

4.35 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD90 |

160 |

100 |

115 |

3.87 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD90 |

200 |

100 |

115 |

3.50 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD90 |

250 |

100 |

115 |

3.41 |

53 |

30 |

30 |

48 |

63 |

78 |

6.5 |

20 |

25 |

5 |

35 |

14 |

|

LD112 |

100 |

120 |

170 |

6.11 |

62 |

35 |

32 |

55 |

72 |

90 |

7.5 |

22 |

30 |

6 |

40 |

16 |

|

LD112 |

125 |

120 |

170 |

5.85 |

62 |

35 |

32 |

55 |

72 |

90 |

7.5 |

22 |

30 |

6 |

40 |

16 |

|

LD112 |

160 |

120 |

170 |

5.26 |

62 |

35 |

32 |

55 |

72 |

90 |

7.5 |

22 |

30 |

6 |

40 |

16 |

|

LD112 |

200 |

120 |

170 |

5.00 |

62 |

35 |

32 |

55 |

72 |

90 |

7.5 |

22 |

30 |

6 |

40 |

16 |

|

LD112 |

250 |

120 |

170 |

4.72 |

62 |

35 |

32 |

55 |

72 |

90 |

7.5 |

22 |

30 |

6 |

40 |

16 |

|

LD140 |

100 |

145 |

180 |

7.38 |

67 |

38 |

36 |

60 |

80 |

100 |

9.5 |

26 |

35 |

6 |

45 |

18 |

|

LD140 |

125 |

145 |

180 |

6.78 |

67 |

38 |

36 |

60 |

80 |

100 |

9.5 |

26 |

35 |

6 |

45 |

18 |

|

LD140 |

160 |

145 |

180 |

6.56 |

67 |

38 |

36 |

60 |

80 |

100 |

9.5 |

26 |

35 |

6 |

45 |

18 |

|

LD140 |

200 |

145 |

180 |

5.82 |

67 |

38 |

36 |

60 |

80 |

100 |

9.5 |

26 |

35 |

6 |

45 |

18 |

|

LD140 |

250 |

145 |

180 |

5.48 |

67 |

38 |

36 |

60 |

80 |

100 |

9.5 |

26 |

35 |

6 |

45 |

18 |

|

LD180 |

125 |

190 |

250 |

10.70 |

86 |

49 |

42 |

70 |

100 |

125 |

13 |

30 |

45 |

8 |

50 |

20 |

|

LD180 |

160 |

190 |

250 |

9.72 |

86 |

49 |

42 |

70 |

100 |

125 |

13 |

30 |

45 |

8 |

50 |

20 |

|

LD180 |

200 |

190 |

250 |

9.12 |

86 |

49 |

42 |

70 |

100 |

125 |

13 |

30 |

45 |

8 |

50 |

20 |

|

LD180 |

250 |

190 |

250 |

8.51 |

86 |

49 |

42 |

70 |

100 |

125 |

13 |

30 |

45 |

8 |

50 |

20 |

|

LD180 |

315 |

190 |

250 |

8.20 |

86 |

49 |

42 |

70 |

100 |

125 |

13 |

30 |

45 |

8 |

50 |

20 |

|

LD250 |

160 |

275 |

300 |

13.00 |

97 |

55 |

50 |

80 |

125 |

155 |

15 |

36 |

55 |

8 |

60 |

26 |

|

LD250 |

200 |

275 |

300 |

11.80 |

97 |

55 |

50 |

80 |

125 |

155 |

15 |

36 |

55 |

8 |

60 |

26 |

|

LD250 |

250 |

275 |

300 |

10.80 |

97 |

55 |

50 |

80 |

125 |

155 |

15 |

36 |

55 |

8 |

60 |

26 |

|

LD250 |

315 |

275 |

300 |

10.00 |

97 |

55 |

50 |

80 |

125 |

155 |

15 |

36 |

55 |

8 |

60 |

26 |

|

LD315 |

160 |

370 |

480 |

20.04 |

113 |

70 |

60 |

90 |

140 |

175 |

18 |

42 |

65 |

10 |

70 |

30 |

|

LD315 |

200 |

370 |

480 |

18.24 |

113 |

70 |

60 |

90 |

140 |

175 |

18 |

42 |

65 |

10 |

70 |

30 |

|

LD315 |

250 |

370 |

480 |

16.79 |

113 |

70 |

60 |

90 |

140 |

175 |

18 |

42 |

65 |

10 |

70 |

30 |

|

LD315 |

315 |

370 |

480 |

15.53 |

113 |

70 |

60 |

90 |

140 |

175 |

18 |

42 |

65 |

10 |

70 |

30 |

|

LD315 |

400 |

370 |

480 |

14.56 |

113 |

70 |

60 |

90 |

140 |

175 |

18 |

42 |

65 |

10 |

70 |

30 |

* Breaking Load With heat treated Plates

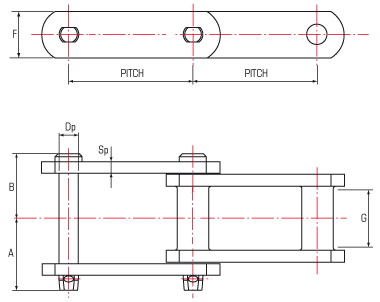

Combination chains for Feed and Washing tables

This series employs cast block with steel sidebars. Blocks are available in LDC grade or stainless steel to special order. The one piece construction of the block makes the combination chain an ideal choice to counter impact and abrasion.

|

Chain |

Pitch |

A |

B |

Dp |

G |

F |

Sp |

Ultimate Strength |

Weight |

|

|

C188 |

mm |

66.27 |

41.90 |

31.75 |

12.7 |

23.88 |

28.70 |

6.00 |

6,400 kg |

5.22 kg/m |

|

in |

2.609 |

1.63 |

1.25 |

0.50 |

0.94 |

1.13 |

0.25 |

14,000 lb |

||

|

C131 |

mm |

78.1 |

42.9 |

49.2 |

15.9 |

28.6 |

38.1 |

9.5 |

11,900 kg |

10.00 kg/m |

|

in |

3.08 |

1.69 |

1.94 |

0.63 |

1.13 |

1.50 |

0.38 |

24,000 lb |

||

|

C102 |

mm |

101.6 |

54.0 |

57.2 |

15.9 |

47.6 |

38.1 |

9.5 |

11,900 kg |

11.15 kg/m |

|

in |

4.00 |

2.13 |

2.25 |

0.63 |

1.88 |

1.50 |

0.38 |

24,000 lb |

||

|

C111 |

mm |

121.9 |

60.3 |

66.7 |

19.1 |

54.0 |

44.5 |

9.5 |

16,400 kg |

13.87 kg/m |

|

in |

4.76 |

2.38 |

2.63 |

0.75 |

2.13 |

1.75 |

0.38 |

36,000 lb |

||

|

C110 |

mm |

152.4 |

52.4 |

55.6 |

15.9 |

47.6 |

38.1 |

9.5 |

11,900 kg |

8.79 kg/m |

|

in |

6.00 |

2.06 |

2.19 |

0.63 |

1.88 |

1.50 |

0.38 |

24,000 lb |

||

|

C132 |

mm |

153.9 |

81.0 |

82.6 |

25.4 |

79.4 |

50.8 |

12.7 |

22,700 kg |

19.52 kg/m |

|

in |

6.06 |

3.19 |

3.25 |

1.00 |

3.13 |

2.00 |

0.50 |

50,000 lb |

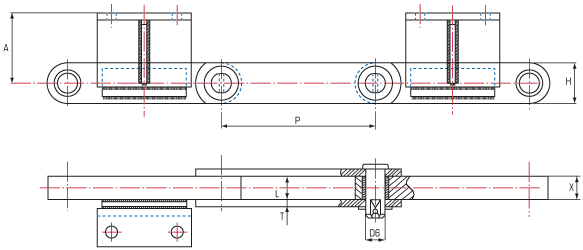

Scraper Reclaimer

Particularly strong and resistant to wear, our scraper chains are designed especially for conveying granular, powder or liquid materials that typically are abrasive. We can ensure accuracy of execution, careful selection of materials and treatments, and state-of-the-art technology providing LDC scraper chains with a greater service life and consistency of performance. Designed to convey granular and powder materials or material resulted from transformation processes, LDC scraper chains can be used on a regular basis in many sectors from agro-food and chemical industries to waste disposal and recycling plants.

|

Chain |

Pitch |

L |

D6 |

A |

H |

X |

T |

|

P |

|||||||

|

mm |

|||||||

|

LD250620 |

250 |

41 |

36 |

125 |

70 |

40 |

12 |

|

LD315850 |

315 |

51 |

42 |

135 |

80 |

50 |

15 |

Bucket Elevator Combination Chain

Specialty chain for continuous discharge type Bucket Elevator in vertical operation, which has superior durability and longer life performance.

LDC long experience in the production of cast combination chains allows them to offer this unique and well proven standard that incorporates a cast manganese plain or duck bill block for bucket mounting.

Operating in twin strand format the groove in the block link engages with friction drives wheels.

The chain bucket elevator is the product that has been introduced and developed by advanced technology,suitable for vertical delivery of powder, granular and bulk materials,it can also improve the abrasive material,such as fly ash, slag, limestone, cement raw materials, cement clinker, cement, coal, dry clay, etc. Material temperature generally does not more than 250°.

The chain bucket is fixed on the high-strength chain as a traction part.When equipped with deep bucket, it is suitable for conveying dry, loose and powdery, granular,massive materials which having good flowability.When equipped with shallow buckets, it is suitable for powdered and granular materials which are slightly damp, easy to agglomerate, poor flowability.