Typical & mostly used roller chains in all most all industrial units to transmit power at any area of plant. These chains are very popular thorought industries to carry out different transmission jobs.

Mild Steel (MS). STATINLESS STEEL (SS), NICKEL PLATED

ANSI & BIS

All sizes from single to tetra strands are available from 35 # to 240 # in ANSI & 05B to 56B

All Industrial Sectors

Caterpillar Drive Chains

Caterpillar Drive Chains are vital in driving drop forged chain conveyors, so they must deliver fatigue-free operation. The U.S. Tsubaki Caterpillar Drive Chain features high-quality roller chain with drive dogs made of one-piece forged, induction-hardened steel.

The entire assembly is designed to operate flawlessly in combination with our forged rivetless chain. Our chain also meets ANSI standards.

All dimensions are nominal values and for reference only

This chain is normally stocked.

Note: Power chains are available with "cam yokes" (normally every 4th pitch) or outboard rollers (normally every 6th pitch).

| Peer Part No. | d | Pitch F | Distance Between Dogs | Roller Width W | Roller Diameter D | Plate Height H | Plate Thickness T | Pin Diameter d | Overall Width F | Dog Height C | Dog Width E | Average Tensile Strength | Average Weight Per PC in LBS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 160Cw/348Dogs | 160Cw/348 Dogs | 2.000 | 12.000 | 1.250 | 1.125 | 1.898 | 0.250 | 0.562 | 2.691 | 2.120 | 0.625 | 58,000 | 87.00 |

| 160Cw/458Dogs | 160Cw/458 Dogs | 2.000 | 8.000 | 1.250 | 1.125 | 1.898 | 0.250 | 0.562 | 2.691 | 2.370 | 1.000 | 58,000 | 89.00 |

| 160C x/678Dogs | 160C x/678 Dogs | 2.000 | 12.000 | 1.250 | 1.125 | 1.898 | 0.250 | 0.562 | 2.691 | 3.070 | 1.260 | 58,000 | 88.00 |

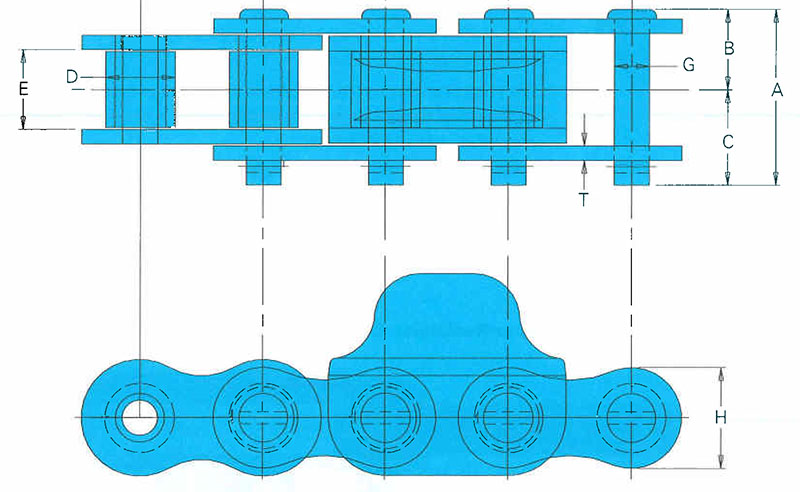

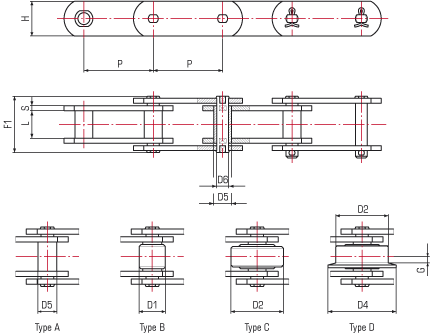

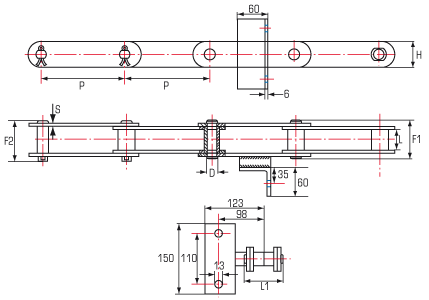

Engineering Steel Paver Chains

LUAN DUNG have extensive experience in the manufacture and application of Paver chains for use as drag bars assemblies in these road surfacing machines. The chains are used in twin strand format with the strands made common with flight bars. Used either as a single or double pair the chains are installed within the delivery hopper of the machine.

LDC Chains produce paver chains as a principal series to original equipment and replacement applications. A multiplicity of chain types are encountered, but all following the same general format. Some of the more popular types encountered are highlighted in this section, but this is by no means exhaustive and for those chains required that are not detailed please contact our sales department.

|

Engineering Steel Paver Chains |

|||||||||||||

|

Chain |

P |

L |

D5 |

D6 |

H |

S |

A |

B |

C |

D |

E |

Attachment |

Breaking Load |

|

mm |

kN |

||||||||||||

|

LD3266 |

75.00 |

18.50 |

15.00 |

10.00 |

25 |

4 |

15 |

32 |

25 |

13.80 |

41 |

4 |

90 |

|

LD3493 |

80.00 |

25.00 |

20.00 |

15.00 |

35 |

5 |

20 |

43 |

40 |

19.80 |

59 |

4 |

178 |

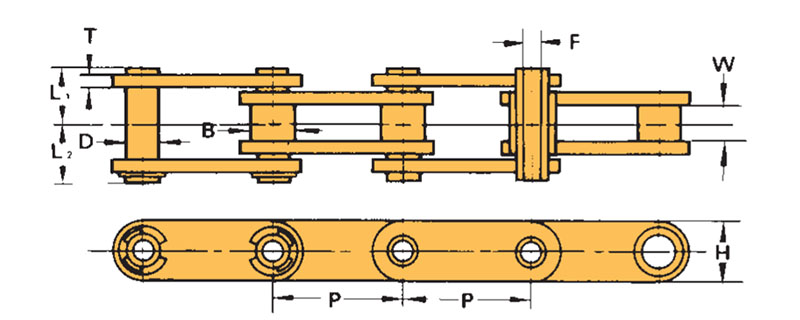

Bush Class Chains

The heavy duty offset sidebar roller chain is designed for drive and traction purposes, and is commonly used on mining equipment, grain processing equipment, as well as equipment sets in steel mills. It is processed with high strength, impact resistance, and wearing resistance, so as to ensure safety in heavy duty applications.

Heavy Duty Offset Sidebar Roller Chain

Design and Processing Advantages

1. Made of medium carbon steel, the offset sidebar roller chain undergoes processing steps like heating, bending, as well as cold pressing after annealing.

2. The pin hole is created by impact extrusion, which increases the inner surface smoothness for the hole. Thus, the matching area between the sidebar and the pin is increased, and the pins offer higher protection against heavy loads.

3. The integral heat treatment for the chain plates and rollers ensures high tensile strength. The pins additionally undergo high-frequency induction heating for the surface after integral heat treatment, ensuring high strength, high surface hardness, and wearing resistance as well. The surface carburizing treatment for the bushings or sleeves guarantees high tensile strength, superb surface hardness, and improved impact resistance. These make sure the heavy duty transmission chain has extended service life.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: Specifications based on standard material and heat treatment. Options of austentic stainless steel plates and hardening stainless materials for pin and bushes available on request.

|

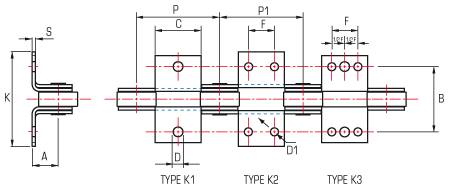

BS K Attachments Integral |

|||||||||||

|

Attachment |

Attachment |

Transverse |

Centre |

Outer |

Hole |

Width Over |

Platform |

Platform |

Attachment |

Breaking |

Attachment |

|

P |

P1 |

B |

D |

D1 |

F |

K |

C |

A |

S |

||

|

mm |

kN |

||||||||||

|

76.2 |

76.2 |

76.2 |

10.5 |

9.2 |

22.2 |

106/115 |

43 |

19.0 |

3.8 |

43 |

K3 |

|

101.6 |

101.6 |

- |

10.5 |

9.2 |

31.8 |

- |

64.0 |

- |

- |

- |

K3 |

|

127.0 |

127.0 |

- |

10.5 |

9.2 |

57.2 |

- |

89.0 |

- |

- |

- |

K3 |

|

152.4 |

152.4 |

- |

10.5 |

9.2 |

57.2 |

- |

114.0 |

- |

- |

- |

K3 |

|

76.2 |

76.2 |

89.0 |

13.7 |

10.5 |

31.8 |

130/136 |

63.5 |

31.8 |

5.1/3.8 |

55 |

K3 |

|

101.6 |

101.6 |

- |

13.7 |

10.5 |

31.8 |

- |

63.5 |

- |

- |

75 |

K3 |

|

152.4 |

152.4 |

- |

13.7 |

10.5 |

57.2 |

- |

114.5 |

- |

- |

- |

K3 |

|

101.6 |

101.6 |

108 |

15.3 |

- |

- |

146/157 |

56.0 |

38.0 |

7.1/5.7 |

110 |

K1 |

|

101.6 |

101.6 |

- |

15.3 |

12.2 |

31.8 |

- |

56.0 |

- |

- |

135 |

K2 |

|

152.4 |

152.4 |

- |

15.3 |

12.2 |

57.2 |

- |

107.0 |

- |

- |

- |

K3 |

|

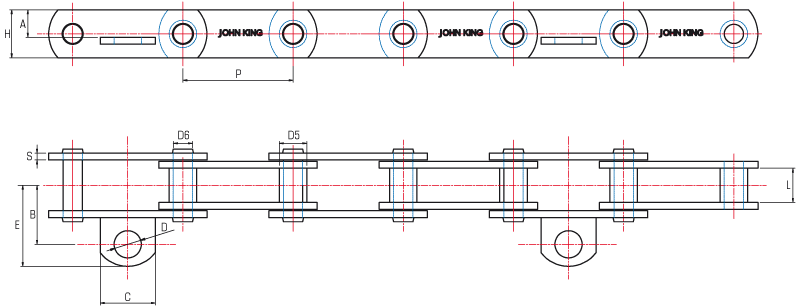

BS Solid Pin Conveyor Chains |

|||||||||||

|

Chain |

P |

Working |

Average |

Rollers |

Bushings |

Between |

Sidebars |

Pins |

|||

|

D2 |

Outside Diameter |

Thickness |

Height |

Diameter |

|||||||

|

D6 |

|||||||||||

|

D5 |

L |

S1 |

S2 |

H |

|||||||

|

mm |

kN |

kN* |

kg/m |

mm |

mm |

||||||

|

SP43/0762/WP |

76.2 |

43 |

70 |

3.83 |

31.75 |

17 |

15 |

4 |

4 |

25 |

14 |

|

SP43/1016/WP |

101.6 |

43 |

70 |

3.71 |

31.75 |

17 |

15 |

4 |

4 |

25 |

14 |

|

SP43/1270/WP |

127 |

43 |

70 |

3.45 |

31.75 |

17 |

15 |

4 |

4 |

25 |

14 |

|

SP43/1524/WP |

152.4 |

43 |

70 |

3.29 |

31.75 |

17 |

15 |

4 |

4 |

25 |

14 |

|

SP75/1016/WP |

101.6 |

75 |

125 |

7.37 |

47.6 |

23.6 |

19 |

5 |

4 |

40 |

19 |

|

SP135/1524/WP |

152.4 |

135 |

200 |

13.81 |

66.7 |

33 |

25.4 |

7 |

5 |

50 |

26.9 |

* Heat treated sidebars – double strength version.

All SP series available with extended pins.

|

BS Hollow Pin Conveyor Chains |

|||||||||||

|

Chain |

P |

Working |

Average |

Rollers |

Bushings |

Between |

Sidebars |

Pins |

|||

|

D2 |

Outside Diameter |

Thickness |

Height |

Diameter |

|||||||

|

D5 |

L |

S1 |

S2 |

H |

D6 |

||||||

|

mm |

kN |

kN* |

kg/m |

mm |

mm |

||||||

|

HP55/1016/WP |

101.6 |

55 |

110 |

6.85 |

47.5 |

23.6 |

19 |

5 |

4 |

40 |

19 |

|

HP110/1524/WP |

152.4 |

110 |

300 |

12.91 |

66.7 |

33 |

25.4 |

7 |

5 |

50 |

26.9 |

* Heat treated sidebars – double strength version.

|

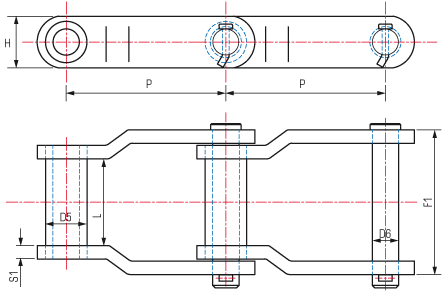

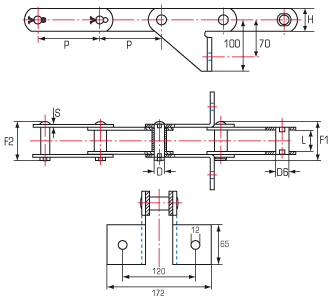

Metric Conveyor Chains ISO 1977 (LDT Series) DIN 8167 |

||||||||||||||

|

Chain |

P |

Working |

Average |

Rollers |

Pins |

Over All Pin & Cotter |

Bushings |

Between |

Sidebars |

|||||

|

Style |

Flange |

Diameter |

Diameter |

Thickness |

Height |

|||||||||

|

Bush Type |

D1 |

D2 |

D4 |

G |

D6 |

F1 |

D5 |

L |

S |

H |

||||

|

mm |

kN |

kN* |

kg/m |

mm |

||||||||||

|

LDT80 |

80 |

80 |

125 |

4.51 |

25 |

50 |

60 |

7 |

12 |

54.5 |

18 |

28 |

5 |

35 |

|

LDT80 |

100 |

80 |

125 |

4.13 |

25 |

50 |

60 |

7 |

12 |

54.5 |

18 |

28 |

5 |

35 |

|

LDT80 |

125 |

80 |

125 |

3.83 |

25 |

50 |

60 |

7 |

12 |

54.5 |

18 |

28 |

5 |

35 |

|

LDT80 |

160 |

80 |

125 |

3.57 |

25 |

50 |

60 |

7 |

12 |

54.5 |

18 |

28 |

5 |

35 |

|

LDT80 |

200 |

80 |

125 |

3.38 |

25 |

50 |

60 |

7 |

12 |

54.5 |

18 |

28 |

5 |

35 |

|

LDT112 |

80 |

112 |

175 |

6.30 |

30 |

60 |

75 |

7.5 |

15 |

63 |

21 |

32 |

6 |

40 |

|

LDT112 |

100 |

112 |

175 |

5.60 |

30 |

60 |

75 |

7.5 |

15 |

63 |

21 |

32 |

6 |

40 |

|

LDT112 |

125 |

112 |

175 |

5.80 |

30 |

60 |

75 |

7.5 |

15 |

63 |

21 |

32 |

6 |

40 |

|

LDT112 |

160 |

112 |

175 |

5.37 |

30 |

60 |

75 |

7.5 |

15 |

63 |

21 |

32 |

6 |

40 |

|

LDT112 |

200 |

112 |

175 |

4.63 |

30 |

60 |

75 |

7.5 |

15 |

63 |

21 |

32 |

6 |

40 |

|

LDT160 |

100 |

160 |

260 |

9.80 |

36 |

70 |

90 |

8.5 |

18 |

72 |

25 |

37 |

7 |

50 |

|

LDT160 |

125 |

160 |

260 |

8.50 |

36 |

70 |

90 |

8.5 |

18 |

72 |

25 |

37 |

7 |

50 |

|

LDT160 |

160 |

160 |

260 |

7.80 |

36 |

70 |

90 |

8.5 |

18 |

72 |

25 |

37 |

7 |

50 |

|

LDT160 |

200 |

160 |

260 |

7.30 |

36 |

70 |

90 |

8.5 |

18 |

72 |

25 |

37 |

7 |

50 |

|

LDT160 |

250 |

160 |

260 |

6.90 |

36 |

70 |

90 |

8.5 |

18 |

72 |

25 |

37 |

7 |

50 |

|

LDT224 |

125 |

224 |

340 |

12.30 |

42 |

85 |

105 |

10 |

21 |

84 |

30 |

43 |

8 |

60 |

|

LDT224 |

160 |

224 |

340 |

11.10 |

42 |

85 |

105 |

10 |

21 |

84 |

30 |

43 |

8 |

60 |

|

LDT224 |

200 |

224 |

340 |

10.20 |

42 |

85 |

105 |

10 |

21 |

84 |

30 |

43 |

8 |

60 |

|

LDT224 |

250 |

224 |

340 |

6.90 |

42 |

85 |

105 |

10 |

21 |

84 |

30 |

43 |

8 |

60 |

|

LDT224 |

315 |

224 |

340 |

8.98 |

42 |

85 |

105 |

10 |

21 |

84 |

30 |

43 |

8 |

60 |

|

LDT315 |

160 |

315 |

520 |

19.20 |

50 |

100 |

124 |

10.5 |

25 |

97 |

36 |

48 |

10 |

70 |

|

LDT315 |

200 |

315 |

520 |

16.70 |

50 |

100 |

124 |

10.5 |

25 |

97 |

36 |

48 |

10 |

70 |

|

LDT135 |

250 |

315 |

520 |

15.60 |

50 |

100 |

124 |

10.5 |

25 |

97 |

36 |

48 |

10 |

70 |

|

LDT315 |

315 |

315 |

520 |

14.70 |

50 |

100 |

124 |

10.5 |

25 |

97 |

36 |

48 |

10 |

70 |

|

LDT315 |

400 |

315 |

520 |

13.80 |

50 |

100 |

124 |

10.5 |

25 |

97 |

36 |

48 |

10 |

70 |

|

LDT450 |

200 |

45 |

70 |

23.90 |

60 |

120 |

149 |

11.5 |

30 |

114 |

42 |

56 |

12 |

80 |

|

LDT450 |

250 |

45 |

70 |

22.12 |

60 |

120 |

149 |

11.5 |

30 |

114 |

42 |

56 |

12 |

80 |

|

LDT450 |

315 |

45 |

70 |

20.65 |

60 |

120 |

149 |

11.5 |

30 |

114 |

42 |

56 |

12 |

80 |

|

LDT450 |

400 |

45 |

70 |

19.45 |

60 |

120 |

149 |

11.5 |

30 |

114 |

42 |

56 |

12 |

80 |

* Breaking Load With heat treated Plates

|

Chains for the Wood Industry |

|||||||||

|

Chain |

Pitch |

Bush/Roller |

Pin |

Plate |

Tensile |

||||

|

Width |

Diameter |

Diameter |

Length |

Thickness |

Height |

||||

|

P |

L |

D6 |

D |

F1 |

F2 |

S |

H |

||

|

mm |

kN |

||||||||

|

M112A100/F2 |

100 |

32 |

21 |

15 |

65 |

73 |

6/6 |

40 |

112 |

|

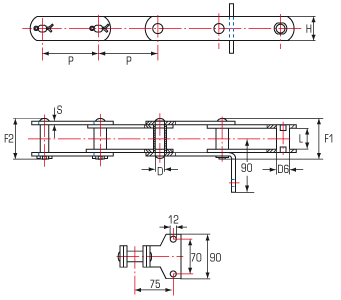

Chains for the Wood Industry |

|||||||||

|

Chain |

Pitch |

Bush/Roller |

Pin |

Plate |

Tensile |

||||

|

Width |

Diameter |

Diameter |

Length |

Thickness |

Height |

||||

|

P |

L |

D6 |

D |

F1 |

F2 |

S |

H |

||

|

mm |

kN |

||||||||

|

M112A100/L2 |

100 |

32 |

21 |

15 |

65 |

73 |

6/6 |

40 |

112 |

|

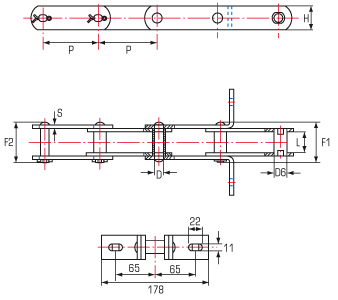

Chains for the Wood Industry |

|||||||||

|

Chain |

Pitch |

Bush/Roller |

Pin |

Plate |

Tensile |

||||

|

Width |

Diameter |

Diameter |

Length |

Thickness |

Height |

||||

|

P |

L |

D6 |

D |

F1 |

F2 |

S |

H |

||

|

mm |

kN |

||||||||

|

M112A100/T2 |

100 |

32 |

21 |

15 |

65 |

73 |

6/6 |

40 |

112 |

Proof Chains Hollow Pin

A Hollow Pin chain helps solve a wide variety of challenging conveying problems. Our standard Mild steel chains and stainless steel chains all feature cold-forged, solid, hollow pins for superior wear resistance and seamless operation. Hollow pin chains have chain pins with through-bore holes for mounting specifically designed attachments. They are often found as chain pairs in conveyance equipment or paternoster elevator

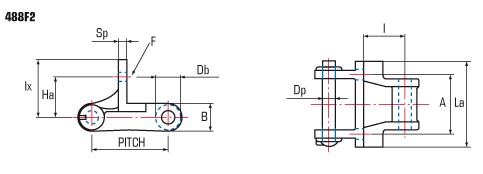

Juice Strainer and Trash Conveyor Chains

Cast pintle chains have been the traditional selection for juice strainers and trash elevators. Engineered steel chains have also been developed as a direct alternative. (E.g. 4103 F29 and E2103) to allow for higher mechanical characteristic and enhanced corrosion resistance. In addition Luan Dung plastic division offer non-metallic alternatives that have proven performance in similar applications.

|

Juice Strainer and Trash Conveyor Chains |

|||||||||||||||||

|

Chain |

Pitch |

Dp |

Db |

B |

Ha |

A |

La |

F |

Sp |

I |

Ix |

Allowable Load |

Ultimate Strength |

Weight |

|||

|

dia. |

length |

Plain |

F2/29 |

||||||||||||||

|

488F2 |

mm |

66.3 |

11.2 |

77.7 |

22.4 |

25.4 |

35.1 |

51.6 |

73.9 |

7.9 |

8.0 |

36.1 |

50.8 |

820 kg |

5,000 kg |

5.2 kg/m |

9.2 kg/m |

|

in |

2.61 |

0.44 |

3.06 |

0.88 |

1.00 |

1.38 |

2.03 |

2.94 |

0.31 |

0.31 |

1.42 |

2.00 |

1,800 lb |

11,000 lb |

|||

|

4103F29 |

mm |

78.0 |

19.0 |

92.2 |

31.8 |

38.1 |

50.8 |

62.0 |

83.3 |

12.7 |

11.0 |

67.1 |

67.1 |

1,600 kg |

10,000 kg |

9.2 kg/m |

13.1 kg/m |

|

in |

3.07 |

0.75 |

3.63 |

1.25 |

1.50 |

2.02 |

2.44 |

3.00 |

0.50 |

0.44 |

2.64 |

2.64 |

3,500 lb |

22,000 lb |

|||

|

E2103 |

mm |

78.0 |

19.0 |

79.5 |

31.8 |

38.1 |

53.1 |

88.9 |

124.0 |

10.0 |

6.4 |

16.0 |

69.9 |

2,200 kg |

13,100 kg |

8.8 kg/m |

13.9 kg/m |

|

in |

3.07 |

0.75 |

3.13 |

1.25 |

1.50 |

2.09 |

3.50 |

4.88 |

0.40 |

0.25 |

0.63 |

2.75 |

4,900 lb |

40,000 lb |

|||

Intermediate Carrier Cast Link Chains LD 907 E51

This is an all Stainless chain made to resist the corrosion from the sugar solution. It consists of a cast link in grade 300 austenitic stainless, and 410 hardened austenitic stainless bushing and headed stud. Also Available in malleable iron if required.

Packing Length: 40 pitches, 3.22m (10.6 feet).

35,000 lb Tensile Strength19.8 KG/m Weight.

| DIMENSION | A | B | C | D | E | F | G | H | I | J | K |

| mm | 80.52 | 161.04 | 16.0 dia | 35.7 dia | 42.42 | 142.0 | 10.0 | 18.29 | 23.88 | 38.1 | 16.2 dia |

| INCHES | 3.17 | 6.34 | 0.63 dia | 1.406 dia | 1.67 | 5.59 | 0.394 | 0.72 | 0.94 | 1.5 | 0.638 dia |

Intermediate carrier cast Link chains LD 4103

Another all stainless chain resistant to corrosion from sugar solution. The cast block, stud and split pin are all austenitic stainless steel. The F29 attachment can be positioned as required.

Packing Length: 40 pitches, 3.12m (10.25 feet).

122 KN ( 27,500 lb ) Tensile Strength

9.22 kg/m Weight of Plain Chain0.50 kg additional Weight of F29 attachment.

| DIMENSION | A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| mm | 78.1 | 67.5 | 50.8 | 38.1 | 90.5 | 19.05 dia | 31.75 dia | 10.3 | 56.4 | 83.4 | 14.0 dia | 29.0 | 47.6 | 14.0 |

| INCH | 3.075 | 2.66 | 2.0 | 1.5 | 3.56 | 0.75 dia | 1.25 dia | 0.41 | 2.22 | 3.28 | 0.55 dia | 1.14 | 1.87 | 0.55 |

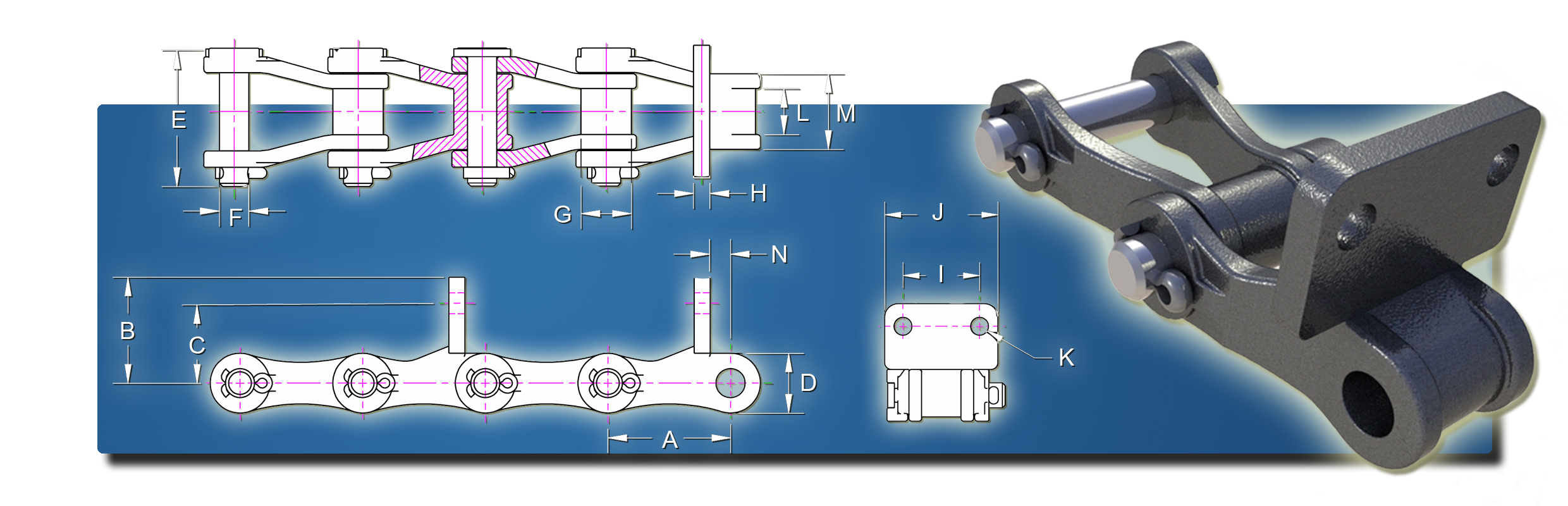

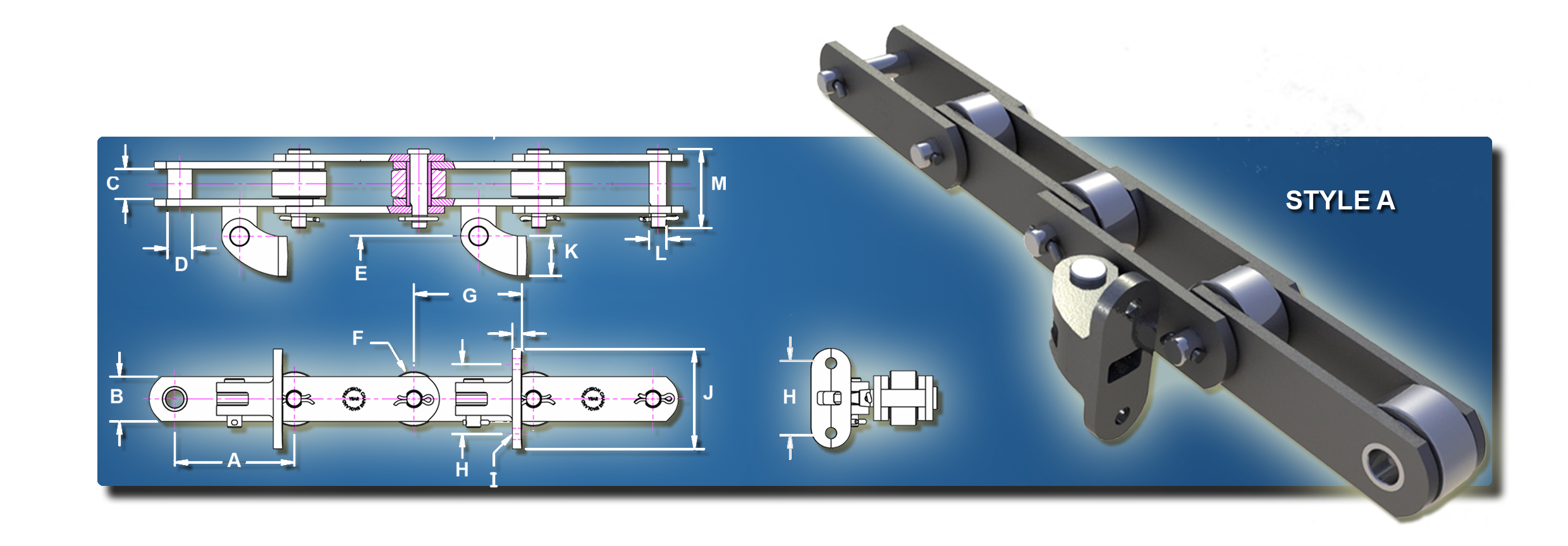

Intermediate Carrier Roller Chains

These chains are also commonly used on the Bagasse conveyor series and come in two alternative styles. One compromised of flat inner and outer bar components (Style A) , and the other assembled using a cranked sidebar instead (Style B). Both chains are more than capable for the application but the design is down to our client preference.

The stud is manufactured from chrome molybdenium alloy steel, hardened and induction hardened on its full circumference. There is a single flat placed on the inside of the link so that corners, which are a stress raiser, are positioned in an area of the sidebar which is in low tension.

The seamless steel bush has a particularly heavy deoth of case hardening to match the stud. No flats are used in order to avoid stress raisers in the area of the sidebar which is in the maximum tension. Rollers are bossed and either hardened or case hardened. We also manufacture all these chains with stud and bush in 431 hardened stainless steel, a grade particularly resistant to corrosion from sugar solutions

| MODEL | CHAIN STYLE | TENSILE STRENGTH |

STUD/ BUSH

BEARING AREA

(mm sqr)

|

RATED WORKING

VALUE

KN

|

WEIGHT OF

PLAIN CHAIN

kg/m

|

WEIGHT OF

LUG + FLIGHT

kg

|

FLIGHT

REFERENCE

|

|

| KN | 1000 lb | |||||||

| LDI 1130 | B | 152 | 34 | 970 | 24.2 | 12.7 | 1.5 | 2C |

| LDI 9060 | A | 311 | 70 | 1100 | 20.7 | 16.7 | 1.0 | 21C |

| LDI 9060 | B | 311 | 70 | 1100 | 27.2 | 16.7 | 1.0 | 21C |

| LDI 2164 | B | 378 | 85 | 1200 | 30.0 | 18.3 | 1.3 | 2C |

| LDI 9061 | A | 378 | 85 | 1100 | 20.7 | 16.5 | 0.9 | 21C |

| LDI 9061 | B | 378 | 85 | 1100 | 27.2 | 16.5 | 0.9 | 21C |

| LDI 2184-2 | B | 445 | 100 | 1200 | 30.0 | 19.4 | 1.3 | 2C |

| LDI 1796 | A | 445 | 100 | 1300 | 24.1 | 18.8 | 1.0 | 21C |

| LDI 1796 | B | 445 | 100 | 1300 | 31.8 | 18.8 | 1.0 | 21C |

| LDI 8184-2 | B | 756 | 170 | 1800 | 34.5 | 21.1 | 1.3 | 2C |

| LDI 8184 | B | 890 | 200 | 1800 | 45.3 | 23.6 | 1.3 | 2C |

Key Dimensions

| DIMENSION | CHAINS | ||||||||||

| 1130 B | 9060 A | 9060 B | 2184 B | 9061 A | 9061 B | 2184-2 B | 1796 A | 1796 B | 8184 B | 8184-2 B | |

| A | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 203.2 | 203.2 |

| B | 50.8 | 50.8 | 50.8 | 50.8 | 57.15 | 57.15 | 55.6 | 57.15 | 57.15 | 76.2 | 69.85 |

| C | 38.1 | 38.1 | 38.1 | 34.93 | 38.1 | 38.1 | 34.93 | 38.1 | 38.1 | 46.03 | 46.03 |

| D | 28.58 | 28.58 | 28.58 | 31.75 | 28.58 | 28.58 | 31.75 | 31.75 | 31.75 | 38.1 | 38.1 |

| E | 87 | 88.9 | 88.9 | 92.08 | 88.9 | 88.9 | 92.08 | 88.9 | 88.9 | 106.35 | 106.35 |

| F | 63.5 | 69.85 | 69.85 | 76.2 | 69.85 | 69.85 | 76.2 | 69.85 | 69.85 | 88.9 | 88.9 |

| G | 142.88 | 111.13 | 111.13 | 142.88 | 111.13 | 111.13 | 142.88 | 111.13 | 111.13 | 168.28 | 168.28 |

| H | 88.9 | 82.55 | 82.55 | 88.9 | 82.55 | 82.55 | 88.9 | 82.55 | 82.55 | 88.9 | 88.9 |

| I | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 |

| J | 127 | 114.3 | 114.3 | 127 | 114.3 | 114.3 | 127 | 114.3 | 114.3 | 127 | 127 |

| K | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 |

| L | 19.05 | 19.05 | 19.05 | 22.23 | 19.05 | 19.05 | 22.23 | 22.23 | 22.23 | 25.4 | 25.4 |

| M | 84.2 | 96 | 96 | 93.73 | 96 | 96 | 96.52 | 100.6 | 100.6 | 122.94 | 122.94 |