Round steel chains

LDC round steel chains are long-lasting, robust and suitable for every possible application. If conveying, driving or hoisting, we provide you with the appropriate round steel chain. Through our long standing experience in the mechanical engineering fields of forming, welding, heat treatment and surface technology, we exaclty know which chain suits best to your applications.

Advantages of round steel chains in comparison to competitive systems:

- Three-dimensional mobility

- Unsusceptible to corrosion

- Robust and durable

- Highly wear-resistant for a long time

- High-strength, as optimally heat-treated

- Low-maintenance when compared to other systems

- Low-noise

- Self-cleaning

- Compact in size

- Simply assembly and disassembly of LDC components in the chain-belt

Round steel chains

Since the 1960s, Round link steel chains have become a proven standard in mining and have developed in the coal mining industry along with Long wall mining, a highly effective means of extraction.

Armoured face conveyors require a chain that will run over long distances and offer flexibility in operation. The main standard is covered by DIN 22252.

|

Round Link Steel Chains |

||||||||

|

Nominal size |

Diameter |

Pitch |

Width |

Gauge Length |

||||

|

d x t |

d |

Tolerance |

t |

Tolerance |

Inside b1 min |

Outside b2 max |

5 x t |

Tolerance |

|

14 x 50 |

14 |

±0.4 |

50 |

±0.5 |

17 |

48 |

250 |

±1.0 |

|

18 x 64 |

18 |

±0.5 |

64 |

±0.6 |

21 |

60 |

320 |

±1.0 |

|

19 x 64.5 |

19 |

±0.6 |

64.5 |

±0.6 |

22 |

63 |

322.5 |

±1.0 |

|

22 x 86 |

22 |

±0.7 |

86 |

±0.9 |

26 |

73 |

430 |

±1.0 |

|

26 x 92 |

26 |

±0.8 |

92 |

±0.9 |

30 |

85 |

460 |

±1.0 |

|

30 x 108 |

30 |

±0.9 |

108 |

±1.1 |

34 |

97 |

540 |

±1.2 |

|

34 x 126 |

34 |

±1.0 |

126 |

±1.3 |

38 |

109 |

630 |

±1.3 |

Elongation at test force 1.6% max. Total elongation at fracture 14% min. Fatigue test 70,000 cycles min.

|

Round Link Steel Chains |

||||||||

|

Nominal size |

Reference number |

Test force |

Breaking force |

Operating force |

Breaking force |

Operating force |

Bend test deflection |

Weight |

|

d x t |

TH |

Min kN |

Min kN |

Max kN |

Min kN |

Max kN |

mm |

kg/m |

|

14 x 50 |

1450TH |

185 |

246 |

154 |

- |

- |

14 |

±1.0 |

|

18 x 64 |

1864TH |

305 |

407 |

254 |

460 |

287 |

18 |

±1.0 |

|

19 x 64.5 |

1964TH |

340 |

454 |

283 |

510 |

318 |

19 |

±1.0 |

|

22 x 86 |

2286TH |

456 |

608 |

380 |

680 |

425 |

22 |

±1.0 |

|

26 x 92 |

2692TH |

637 |

850 |

531 |

960 |

600 |

26 |

±1.0 |

|

30 x 108 |

30108TH |

848 |

1130 |

707 |

1270 |

795 |

30 |

±1.2 |

|

34 x 126 |

34126TH |

1090 |

1450 |

907 |

1640 |

1026 |

34 |

±1.3 |

Round Link Deep Case Hardened Chains

For use with abrasive material, or where excessive friction occurs case hardened chain may increase operational life considerably over that of standard chains.

Based on DIN 22252:2001 Round link steel chains. Additionally proof loaded and tested.

|

Round Link Steel Chains |

|||||||

|

Nominal |

Ref. |

Pitch |

Width |

Test |

Breaking |

Weight |

|

|

Inside min. |

Outside max. |

||||||

|

d x t |

mm |

min. kN |

kg/m |

||||

|

14 x 50 CH |

14/50/CH |

50 |

16.5 |

47 |

74 |

128 |

4.1 |

|

16 x 64 CH |

18/64/CH |

64 |

20 |

55 |

96 |

160 |

5.1 |

|

19 x 75 CH |

19/75/CH |

75 |

22 |

63 |

135 |

225 |

7.6 |

|

22 x 86 CH |

22/86/CH |

86 |

26 |

75 |

183 |

304 |

9.5 |

|

26 x 100 CH |

26/100/CH |

100 |

31 |

87 |

255 |

425 |

13.3 |

|

30 x 120 CH |

30/120/CH |

120 |

36 |

101 |

340 |

566 |

17.5 |

|

34 x 136 CH |

34/136/CH |

136 |

39 |

113 |

425 |

710 |

23.8 |

Proof Strength 240 N/mm2, Breaking Force 400 N/mm2, Surface Hardness 800HV 40, Carburizing Depth 0.09d, Hardening Depth 0.05d, Material: chrome-Nickel Alloy Steel, All dimensions in mm.

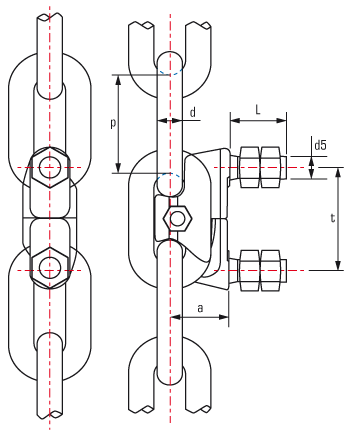

BC Bucket Clamps

Special bucket attachments are available for the CH series chain to be used on vertical bucket elevators. They are designed to operate with friction drives and tooth sprocket wheels.

The bracket allows continuous strands to be employed and operational reliability is increased as they are not an integral part of the haulage member simply an addition. Clamps can be reused when base chain is worn.

|

BC Bucket Clamps |

||||||||

|

Clamp |

Chain |

t |

d |

a |

L |

d5 |

Weight |

|

|

mm |

kg/pc |

|||||||

|

BC16 |

16 x 64 CH |

63 |

64 |

16 |

37 |

40 |

M16 |

0.75 |

|

BC19 |

19 x 75 CH |

80 |

75 |

19 |

47 |

50 |

M20 |

1.3 |

|

BC22 |

22 x 86 CH |

91 |

86 |

22 |

52 |

55 |

M24 |

2.2 |

|

BC26 |

26 x 100 CH |

105 |

100 |

26 |

57 |

58 |

M24 |

2.6 |

|

BC30 |

30 x 120 CH |

126 |

120 |

30 |

71 |

65 |

M30 |

4.5 |

|

BC34 |

34 x 136 CH |

147 |

136 |

34 |

81 |

75 |

M36 |

7.1 |