Keep Your Operation Moving with LUAN DUNG Chain

LUAN DUNG Chains are designed to exceed the listed ultimate strength ratings. These ratings are very significant. Chains with greater ultimate strength have higher actual yield and greater fatigue strength. With LUAN DUNG chains, you get extra reserve strength to withstand high shock loads.

Precision Manufacturing Means Greater Fatigue Strength

LUAN DUNG Engineering Class Drive Chains are built to withstand the most rugged conditions. We use the latest manufacturing and heat-treating techniques to manufacture every component. Each component is carefully machined to close tolerances to ensure precise pitch control for smooth sprocket/chain interaction. That means longer service life for chain and sprockets.

Add the Power of Alloy

When parts require extra hardness, we use alloy steel to make the components. This provides more uniform core strength, which is particularly important for heavy duty applications. Every LUAN DUNG Chain with an ultimate strength rating higher than 112,000 pounds is made entirely of alloy steel. All LUAN DUNG Chains are furnished with alloy steel pins.

Reduce Maintenance Costs and Downtime

LUAN DUNG Chains stand up to the toughest environments for hour after hour of uninterrupted service.

- Optimum strength

- Fatigue resistant

- Pre-tested

- Alloy steel parts

- Press fit construction

- Accurate pitch control

Your equipment is on the line. Count on LUAN DUNG Chain.

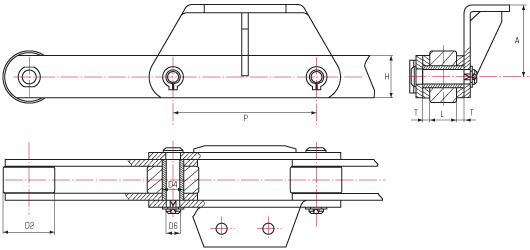

Tram Chains

Tram chains are based on standard transmission chain construction but used in feeder applications on continuous mining machinery. The chains are operated in twin strand format with flight bars making the two strands common. Typical pitches are 2.00 “(50.8 mm) and 2.50” (63.50 mm). Materials are enhanced to ensure higher strengths and wear resistance.

|

Tram Chains |

||||||||||||||||

|

Chain Number |

Pitch |

Style |

Chain Width |

Inside |

Pins |

Bushings |

Rollers |

Sidedbars |

Approx. |

|||||||

|

Overall |

Head to CL |

End to CL |

Diameter |

Material |

Diameter |

Material |

Diameter |

Material |

Thickness |

Height |

MateriAl |

|||||

|

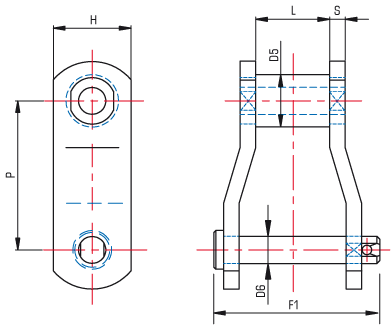

F+F1 |

F |

F1 |

L |

D6 |

D5 |

D2 |

T |

H |

||||||||

|

inches |

inches |

lbs/ft |

||||||||||||||

|

LDC2 |

2.00 |

A |

3.38 |

1.44 |

1.72 |

1.25 |

0.72 |

AHT |

1.13 |

ACH |

- |

- |

0.31 |

1.88 |

AHT |

8.3 |

|

LDC645 |

2.50 |

B |

3.72 |

1.69 |

2.00 |

1.50 |

0.88 |

AHT |

1.13 |

ACH |

1.56 |

AHT |

0.38 |

2.13 |

AHT |

13.5 |

|

LDC6414 |

2.50 |

B |

4.13 |

1.91 |

2.00 |

1.50 |

0.88 |

AHT |

1.13 |

ACH |

1.56 |

AHT |

0.44 |

2.13 |

AHT |

14.5 |

Material AHT = alloy heat treated ACH = alloy case hardened.

JKM6414 sidebar thickness on roller links is .50” and pin link .44”

JKM2 is a bushing type chain and does not have rollers

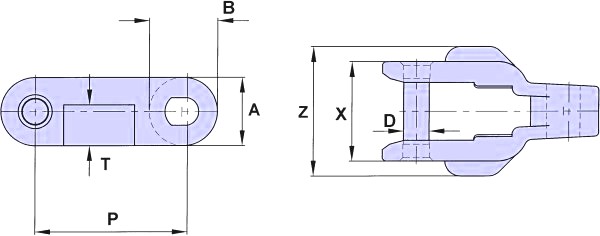

Maxi Chains

This LUAN DUNG works standard includes a range of crank link steel bush chains that offer maximum versatility either in conveying or elevating applications. This series was originally developed to offer an all steel direct replacement for the Cast Bush and Pintle chains. Materials employed, with case hardened alloy steel pin and bush ensure reliable performance.

The crank link construction is a more convinient and effective style. One link can be added or removed if chain length is altered. Any variety of attachments can be fabricated and welded to the base chain. This is generally K style but F, G and S are also popular.

|

Maxi Series |

|||||||||

|

Chain |

Pitch |

Over-all |

Bushing |

Between |

Sidebars |

Sidebars |

Pins |

Average |

Average |

|

P |

F1 |

D5 |

L |

S |

H |

D6 |

|||

|

mm |

kg |

kg/m |

|||||||

|

LDC-MX603 |

76.2 |

88 |

22.5 |

38 |

8 |

40 |

14 |

20,000 |

11.02 |

|

LDC-MX503 |

76.72 |

86 |

27.8 |

38 |

8 |

40 |

14 |

20,000 |

9.25 |

|

LDC-MX604 |

101.6 |

117 |

25 |

57 |

10 |

50 |

16 |

27,500 |

14.92 |

|

LDC-MX704 |

103.1 |

123 |

30 |

57 |

10 |

55 |

18 |

35,000 |

22.63 |

|

LDC-MX504 |

103.1 |

110 |

33.3 |

50 |

10 |

50 |

16 |

27,500 |

12.66 |

|

LDC-MX600 |

153.4 |

110 |

28.6 |

50 |

10 |

50 |

18 |

30,000 |

15.51 |

|

LDC-MX500 |

153.5 |

110 |

32 |

50 |

10 |

40 |

18 |

25,000 |

8.95 |

CC600 Chain

Our CC 600 Conveyor chains are manufactured in malleable iron with steel pins, with pins that are unhardened.

To meet the challenge of the application environment this chain has been developed with the following features:

- Stud ends flush with link.

- Large rubbing areas top and bottom.

- Iron link, softer than the track and self-lubricating

- Corrosion resisting properties.

For further advice, or to find out how our range of chain and sprockets can enhance your application, follow the link below and contact our team.

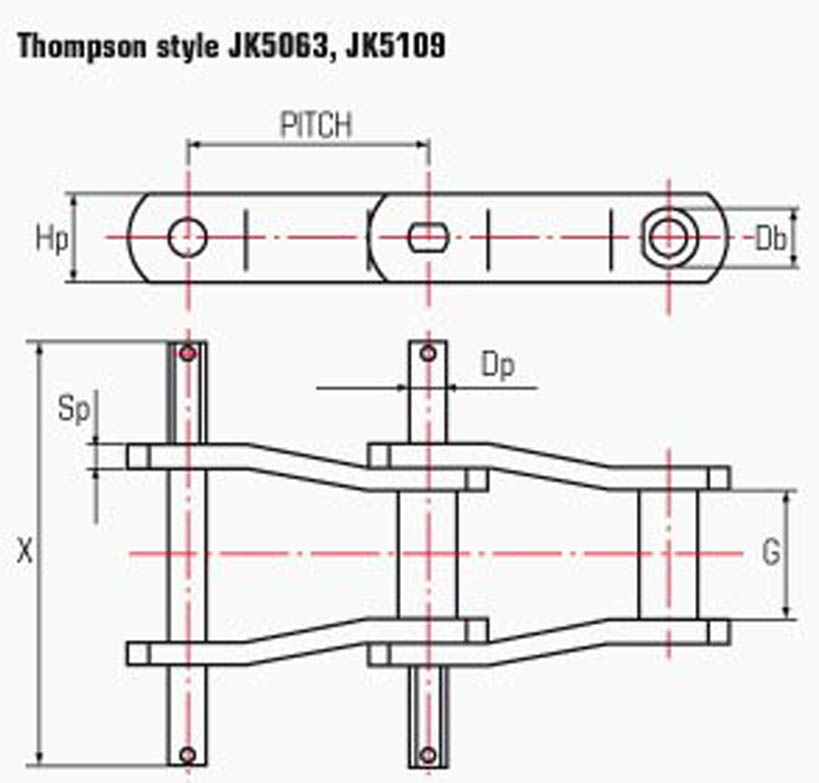

Boiler grate chains

Kings cast chain tradition has allowed them to apply expertise in the development of improved materials for moving grate applications. This hostile environment demands a material that can perform at elevated temperatures and conditions of high abrasion. In addition to the running gear, the related grate castings are also available.

|

Boiler Grate Chains |

|||||||||

|

Chain |

Pitch |

Dp |

Hp |

Db |

G |

Sp |

X |

Ultimate Strength |

|

|

LD472 |

mm |

101.0 |

17.0 |

38.0 |

25.4 |

50.8 |

10.0 |

119.0 |

n/s |

|

in |

3.98 |

0.67 |

1.50 |

1.00 |

2.00 |

0.38 |

4.69 |

n/s |

|

|

LD5063 |

mm |

101.6 |

15.7 |

38.0 |

25.4 |

54.1 |

10.0 |

179.3 |

22,700 kg |

|

in |

4.00 |

0.63 |

1.50 |

1.00 |

2.13 |

0.38 |

7.06 |

50,000 lb |

|

|

LD109 |

mm |

101.6 |

15.7 |

38.0 |

25.4 |

55.6 |

10.0 |

178.6 |

30,500 kg |

|

in |

4.00 |

0.63 |

1.50 |

1.00 |

2.19 |

0.38 |

7.03 |

67,000 lb |

|

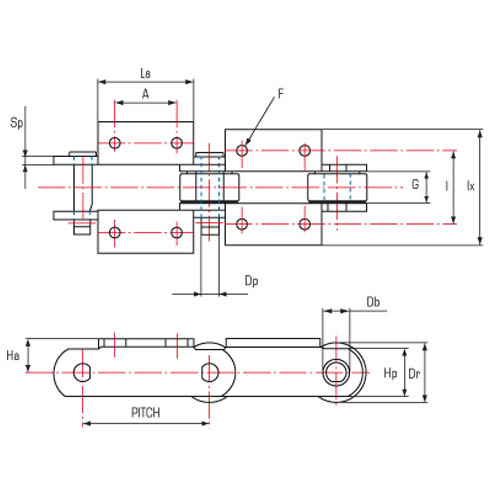

Main cane and auxilliary carrier chains

LDC cane carrier chains are fabricated engineering class designed to meet the most demanding service requrements in sugar mills. Experience allows LDC to select optimum materials and heat treatment conditions to maximise reliability and service life. “Climax” calibration during manufacture ensures accurate matching of strands for duplex or triplex operation.

|

Main Cane and Auxilliary Carrier Chains |

||||||||||||||||

|

Chain |

Pitch |

Dp |

Dr |

Hp |

G |

Db |

Ha |

A |

La |

F |

Sp |

I |

Ix |

Allowable Load |

Ultimate Strength |

|

|

JKR0904 |

mm |

101.6 |

17.5 |

50.8 |

44.5 |

50.8 |

25.4 |

79.5 |

82.6 |

108.0 |

9.7 |

7.9 |

77.7 |

445.5 |

2,200 kg |

18,200 kg |

|

in |

4.00 |

0.69 |

2.00 |

1.75 |

2.00 |

3.13 |

3.13 |

3.24 |

4.25 |

0.38 |

0.31 |

3.06 |

1.75 |

4,850 Ib |

40,000 Ib |

|

|

JKR2178 |

mm |

152.4 |

22.22 |

69.85 |

57.15 |

35 |

31.75 |

41.14 |

76.2 |

114.3 |

12.7 |

9.52 |

110.9 |

142.7 |

3227 kg |

25,454 kg |

|

in |

6.00 |

0.87 |

2.75 |

2.25 |

1.38 |

1.25 |

1.62 |

3.00 |

4.5 |

0.5 |

0.37 |

4.37 |

5.62 |

7,100 Ib |

56,000 Ib |

|

|

JKR09060 |

mm |

152.4 |

19.1 |

69.9 |

50.8 |

38.1 |

28.7 |

111.3 |

82.6 |

114.3 |

12.7 |

9.7 |

88.9 |

50.8 |

2,900 kg |

27,200 kg |

|

in |

6.00 |

0.75 |

2.75 |

2.00 |

1.50 |

1.13 |

4.38 |

3.24 |

4.50 |

0.50 |

0.38 |

3.50 |

2.00 |

6,350 Ib |

60,000 Ib |

|

|

JKR2124 |

mm |

152.4 |

19.05 |

69.85 |

50.8 |

35 |

28.7 |

41.14 |

76.2 |

114.3 |

12.7 |

9.52 |

117.3 |

142.7 |

2,750 kg |

28,636 kg |

|

in |

6.00 |

0.75 |

2.75 |

2 |

1.38 |

1.13 |

1.62 |

3.00 |

4.50 |

0.50 |

0.37 |

4.62 |

5.62 |

6,050 Ib |

63,000 Ib |

|

|

JKR2198 |

mm |

152.4 |

22.22 |

69.85 |

57.15 |

35 |

33.02 |

41.14 |

76.2 |

114.3 |

12.7 |

12.7 |

110.9 |

152.4 |

3,545 kg |

29,090 kg |

|

in |

6.00 |

0.87 |

2.75 |

2.25 |

1.38 |

1.30 |

1.62 |

3.00 |

4.50 |

0.50 |

0.5 |

4.37 |

6.00 |

7,800 Ib |

64,000 Ib |

|

|

JKR2129 |

mm |

228.6 |

19.05 |

82.5 |

57.2 |

37.1 |

33.02 |

44.95 |

101.8 |

152.4 |

15.24 |

9.5 |

146.0 |

208.7 |

3,300 kg |

30,000 Ib |

|

in |

9 |

0.75 |

3.25 |

2.25 |

1.46 |

1.30 |

1.77 |

4.01 |

6.00 |

0.60 |

0.37 |

5.75 |

8.22 |

7,275 Ib |

66,000 Ib |

|

|

JKR2315 |

mm |

228.6 |

22.23 |

76.2 |

63.5 |

43.0 |

38.10 |

44.95 |

139.7 |

177.8 |

13.97 |

9.5 |

152.4 |

211.0 |

3,500 kg |

32,000 kg |

|

in |

9 |

0.87 |

3 |

2.5 |

1.69 |

1.50 |

1.77 |

5.50 |

7.00 |

0.55 |

0.37 |

6.00 |

8.31 |

7,700 Ib |

70,400 Ib |

|

|

JKR09061 |

mm |

152.4 |

19.1 |

69.9 |

57.2 |

38.1 |

28.7 |

111.3 |

82.6 |

114.3 |

12.7 |

9.7 |

88.9 |

50.8 |

2,900 kg |

38,600 kg |

|

in |

6.00 |

0.75 |

2.75 |

2.25 |

1.50 |

1.13 |

4.38 |

3.24 |

4.50 |

0.50 |

0.38 |

3.50 |

2.00 |

6,350 lb |

85,000 Ib |

|

|

JKR2800 |

mm |

203.1 |

25.4 |

88.9 |

69.85 |

35 |

38.1 |

55.37 |

82.5 |

127.0 |

15.74 |

12.7 |

131.5 |

172.9 |

4,454 kg |

42,727 kg |

|

in |

8.00 |

1 |

3.5 |

2.75 |

1.38 |

1.50 |

2.18 |

3.25 |

5.00 |

0.62 |

0.5 |

5.18 |

6.81 |

9,800 Ib |

94,000 Ib |

|

|

JKR1796 |

mm |

152.4 |

22.4 |

69.9 |

57.2 |

38.1 |

38.1 |

111.3 |

82.6 |

114.3 |

12.7 |

9.7 |

88.9 |

50.8 |

3,400 kg |

45,400 kg |

|

in |

6.00 |

0.88 |

2.75 |

2.25 |

1.50 |

1.25 |

4.38 |

3.24 |

4.50 |

0.50 |

0.38 |

3.50 |

2.00 |

7,500 Ib |

100,000 Ib |

|

|

JKR09063 |

mm |

152.4 |

23.9 |

76.2 |

60.5 |

38.1 |

31.8 |

143.0 |

88.9 |

127.0 |

12.7 |

10.4 |

100.1 |

50.8 |

3,800 kg |

63,500 kg |

|

in |

6.00 |

0.94 |

3.00 |

2.38 |

1.50 |

1.25 |

5.63 |

3.50 |

5.00 |

0.50 |

0.41 |

3.94 |

2.00 |

8,300 Ib |

140,000 Ib |

|

* Roller Diameter Dr can be changed to suit customer requirements.

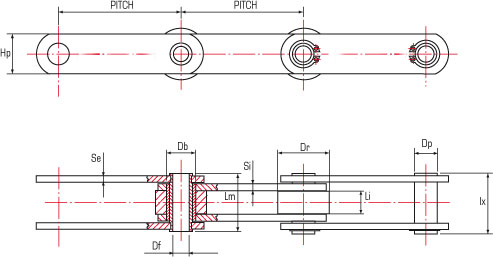

Cane harvester chains

Climax harvester chains come from the British standard but include heat treated sidebars for ‘double strength’ and case carborised pins, bushes and rollers for optimum abrasion resistance.

|

Cane Harvester Chains |

||||||||||||||

|

Chain |

Pitch |

Li |

Dr |

Db |

Df |

Dp |

Hp |

Si |

Se |

Lm |

Ix |

Ultimate Strength |

Weight |

|

|

LD 27/0508/P |

mm |

50.8 |

15.0 |

31.8 |

18.0 |

10.2 |

14.0 |

25.0 |

4.0 |

4.0 |

36.0 |

44.0 |

2,700 kg |

4.0 kg/m |

|

in |

2.00 |

0.59 |

1.25 |

0.71 |

0.40 |

0.55 |

0.98 |

0.16 |

0.16 |

1.42 |

1.73 |

6,000 lb |

||

|

LD 27/0508/R1.5 |

mm |

50.8 |

15.0 |

31.8 |

18.0 |

10.2 |

14.0 |

25.0 |

4.0 |

4.0 |

36.0 |

44.0 |

2,700 kg |

4.2 kg/m |

|

in |

2.00 |

0.59 |

1.25 |

0.71 |

0.40 |

0.55 |

0.98 |

0.16 |

0.16 |

1.42 |

1.73 |

6,000 lb |

||

|

LD 55/0635/P |

mm |

63.5 |

19.0 |

47.6 |

23.6 |

13.2 |

19.0 |

40.0 |

5.0 |

4.0 |

44.0 |

51.0 |

5,500 kg |

n/s |

|

in |

2.50 |

0.75 |

1.87 |

0.93 |

0.52 |

0.75 |

1.57 |

0.20 |

0.16 |

1.73 |

2.01 |

12,000 lb |

||

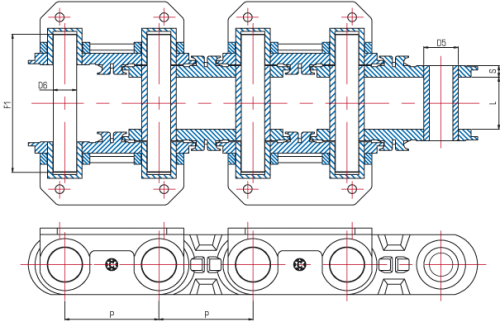

Central Chainfor High Output Bucket Elevators

The New Generation central strand high duty elevator chain has proven performance in the most demanding elevator applications. The construction is simple and assembly or shortening of chain lengths can be achieved with comparative ease. The K style attachment links are mounted on the outer link pin retention sleeves and made common with the bucket fixings.

The secret of success is the employment of optimum materials and heat treatments and the incorporation of a free rotating pin which allows wear to take place on the full diameter. This reduces the wear rate, pitch extension and therefore extends service life.

|

Central Chain for High Output Bucket Elevators |

||||||

|

Chain |

Pitch |

Overall |

Bushings |

Between |

Sidebars |

Average |

|

P |

F1 |

D5 |

L |

S |

||

|

mm |

Kg |

|||||

|

LD 180 200 |

180 |

50 |

80 |

106 |

20 |

204,000 |

|

LD 180 150 |

180 |

40 |

66 |

100 |

22 |

153,000 |

|

LD 200 80 |

180 |

38 |

55 |

85 |

15 |

81,600 |

|

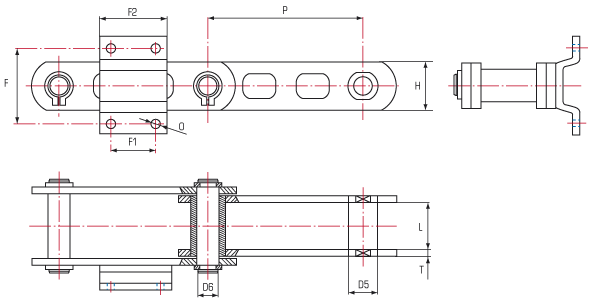

Deep Bucket San Conveyor POL Series |

||||||||||||

|

Chain |

Pitch |

L |

O |

D5 |

D6 |

F |

F1 |

F2 |

H |

T |

Flanged |

Axle Diameter |

|

P |

||||||||||||

|

mm |

||||||||||||

|

LDC 200200 |

200 |

45 |

14 |

32 |

22 |

110 |

60 |

100 |

50 |

8 |

50 |

22-28 |

|

LDC 250320 |

250 |

65 |

18 |

45 |

32 |

150 |

80 |

120 |

70 |

10 |

60 |

32-40 |

|

LDC 250480 |

250 |

67 |

18 |

50 |

35 |

150 |

80 |

120 |

80 |

12 |

70 |

35-45 |

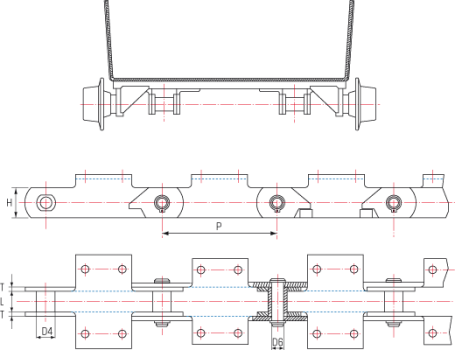

Scraper Reclaimer

The chains can be equipped with different types of scrapers: bent, welded, double bent, and can be fitted with cleaners made of plastic.

Made with a strong riveting system, pins with anti-rotation plates, and treatments with specific depths, all of which ensure performance, loading capacity and service life well above average.

The chains available are made of different materials: case hardening steel, hardened and tempered steel, and stainless steel.

|

Scraper Reclaimer PH Series |

||||||||

|

Chain |

Pitch |

L |

D6 |

D4 |

D2 |

H |

T |

A |

|

P |

||||||||

|

mm |

||||||||

|

LD 2501000 |

250 |

58 |

42 |

50 |

130 |

100 |

15 |

135 |

|

LD 3151100 |

315 |

60 |

36 |

54 |

130 |

100 |

15 |

- |

|

LD 4001100 |

400 |

70 |

36 |

54 |

130 |

100 |

15 |

- |

Pan Conveyor

A typical means of transporting clinker is with a pan or bucket. The LD Series with K style for underside

Fixing to the pan. For the former it is typical to see guide rollers mounted on the chain pin or axle whilst for the latter the guide roller is generally a separate unit fixed to the pan. Clearly the chain is not directly exposed to the material which offers advantage. All types of chains within this category can be manufactured.

|

Pan Conveyor |

||||||

|

Chain |

Pitch |

L |

D4 |

D6 |

H |

T |

|

P |

||||||

|

mm |

||||||

|

LD 200150 |

200 |

35 |

26 |

18 |

45 |

6 |

|

LD 250250 |

250 |

40 |

32 |

20 |

60 |

8 |

|

LD 250350 |

250 |

45 |

36 |

25 |

65 |

10 |

|

LD 250400 |

250 |

45 |

40 |

26 |

70 |

10 |

|

LD 250450 |

250 |

50 |

42 |

30 |

70 |

10 |

|

LD 250500 |

250 |

60 |

44 |

30 |

80 |

10 |

|

LD 250650 |

250 |

60 |

44 |

30 |

80 |

12 |

|

LD 250850 |

250 |

60 |

54 |

36 |

100 |

12 |